About US

%

Years of Experience

+

Clients Served

Company Overview:

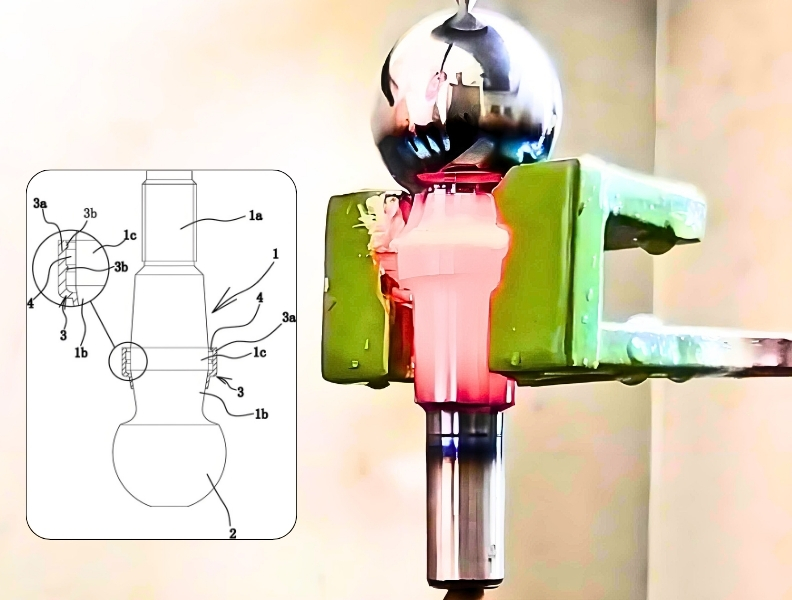

We are a leading automotive parts manufacturer with a factory spanning over 1,000 square meters, specializing in the production of Stabilizer Links, Center Links, Tie Rod Ends, Control Arms, Ball Joints, Pitman Arms, and Idler Arms.

Production Facilities:

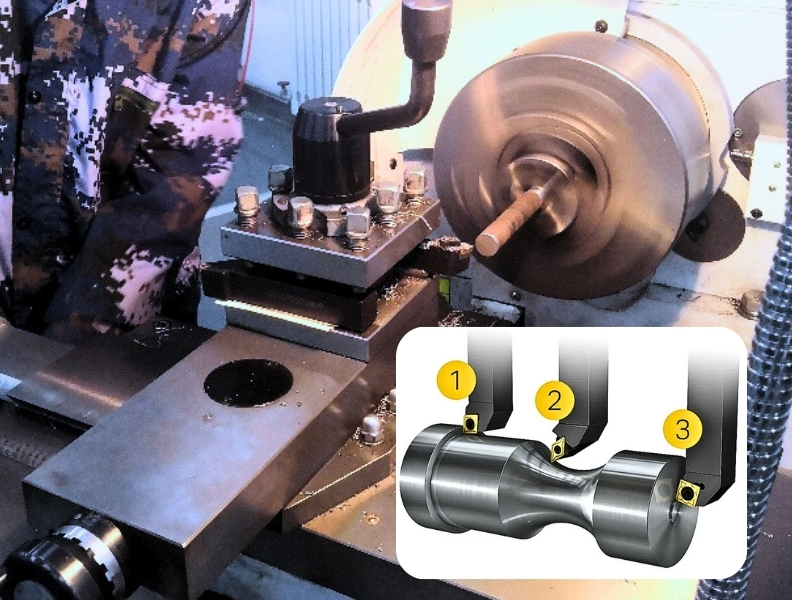

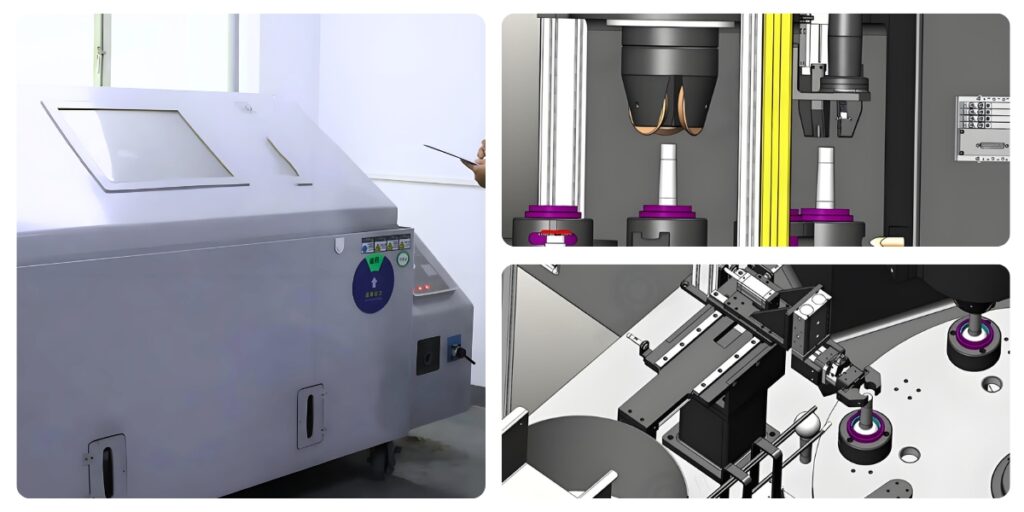

Our manufacturing facility is equipped with advanced technologies including:

1 stamping line

8 stamping presses

20 welding robots

5 CNC lathes

4 CNC milling machines

Operational Efficiency:

Our integrated production system features:

AGV material handling carts

A comprehensive compressed air system

These allow for efficient operations and superior results.